24/7 ONLINE SUPPORT

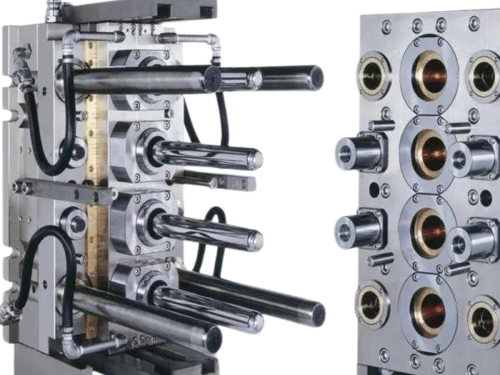

Injection Molding Machines

The Role Of Wear Plates In Injection Moulds

In making plastic molds, the processing of wear plates aims to reduce friction caused by slider movement. This is important to ensure smooth movement of the slider, which in turn increases the service life of the plastic mold.

The Important Of Wear Plate For Injection Mould

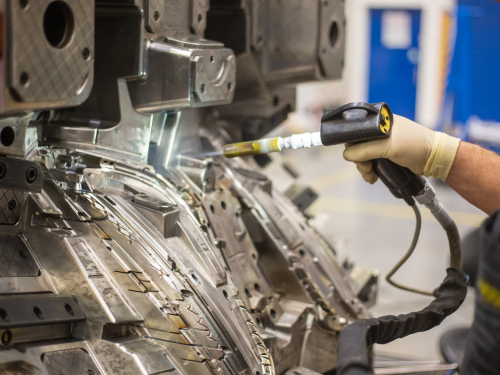

Injection molding has a very vital role in various aspects of modern life, including the application of tools, aviation, aerospace, electronics, machines, ships and cars, and many more. Therefore, the quality of the retention wear plate in injection molding becomes very important. High quality wear plates in injection molds can increase the service life of injection molding machines by providing good impact resistance and excellent corrosion resistance. They have been proven to perform well in injection molding machine applications, automobile stamping molds, tire molds, factory machinery (such as excavators, etc.), and various other industries.

Injection Mould Component – Striper Plate Bush Manufacturer

Striper Plate Bush bronze wear plates are used to direct and control linear movement under gravity. Although first developed for metal stamping dies, these wear plates are widely used in dies, specialty machines, and heavy equipment.

Oiless.co.id provides retention wear plates that combine the wear resistance and high load-carrying capabilities of copper alloys with the environmentally friendly, self-lubricating properties of a solid lubricant. This product can be processed with various oil grooves and oil holes on the friction surface. Once the solid lubricant is embedded, the product can adapt to a wide range of environmental conditions without the need for refilling or maintenance during use. These products are often used in high load, intermittent motion, or reciprocating motion applications.

If you’re ready to get started, you can request a quote to send us your specifications or ask for more details.

Get Bronze Wear Plates Built To Your Specifications

We can create precision wear plates to your exact specifications using a variety of metal component manufacturing techniques, specialty materials, and state-of-the-art equipment. From rapid prototyping to quick-turn delivery at virtually any scale, contact us for more information!