24/7 ONLINE SUPPORT

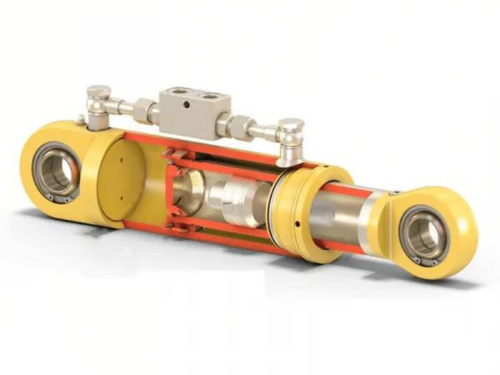

Hydraulic Cylinder

Quality Hydraulic Cylinder Bushings

Hydraulic cylinder bushings are common parts found in many types of heavy equipment, including excavators, bulldozers, cranes, trucks, and more. While the engine, transmission, tires, and tracks are responsible for moving the machine itself, the hydraulic cylinders are designed to move their specific parts. When the boom extends, thickness is raised, or the bucket is tilted, these movements are often controlled by hydraulic cylinders. Therefore, the quality and optimal performance of hydraulic cylinder bushings is essential to ensure the smooth and safe functioning of the machine.

Bronze Components for the Hydraulic Industry

Hydraulic cylinder bushings are one of the key components in the hydraulic transmission system, and their reliability and performance directly affect the function of the overall hydraulic system. The hydraulic cylinder sleeve is a very important executive element in the system. One of the main advantages of a hydraulic transmission is its small size, light weight, and large load-bearing capacity. Additionally, this system has a wide speed range.

Another advantage of the hydraulic transmission system is the ability to easily adjust speed steplessly. This system can also be set up easily and flexibly, using microelectronic technology so that automatic control can be achieved easily. Overload protection capabilities can also be implemented in this system.

In addition, the hydraulic transmission system meets the characteristics of construction machines with heavy workloads and harsh working conditions. This makes it an ideal choice for a variety of applications in the construction and heavy equipment industries. Thus, the reliability of hydraulic cylinder bushings is critical to ensure optimal performance of the hydraulic transmission system.

How Do Hydraulic Cylinder Bushings Work ?

In a hydraulic system, the hydraulic cylinder functions as a force transfer to convert hydraulic energy into mechanical movement. The cylinder is driven by a hydraulic pump that pumps hydraulic oil into the cylinder chamber, producing pressure that pushes or pulls the piston rod into or out of the cylinder. This piston movement is then transmitted to components connected to the cylinder, thereby moving or controlling equipment or machines.

This process allows precise control of motion, whether in pushing, pulling, rotating or pushing different components in a variety of applications. By using hydraulic oil as a power transmission medium, this system is able to provide quite large power in a relatively small size and can be easily adjusted to meet various operational needs. Additionally, this capability provides significant flexibility in the use of hydraulic systems in a variety of industries and applications.

Self-lubricating & Costing Save Hydraulic Bearing

In applications involving continuous compression motion, self-lubricating bronze bushings are often the ideal choice. This is because they are effective in reducing friction, resistant to heat, and have lubricating properties that can minimize damage caused by dirt in the hydraulic oil. In addition, the presence of this bronze bushing can prevent friction between copper and iron metal, thereby avoiding potential damage to components in the hydraulic cylinder. Thus, proper use of bronze bushings can improve the overall performance and service life of the hydraulic system.

Hydraulic Cylinder Bronze Sleeve Bearing

As a strong and long-lasting bearing alternative, our hydraulic cylinder bushings are usually made from tin bronze, with certain types particularly suitable, such as 663 tin bronze. This material is an ideal choice for applications in hydraulic cylinders due to its strength and resistance to pressure and wear tall one. 663 tin bronze not only consists of tin, but also contains zinc, lead and other strengthening elements, thereby providing the optimal combination of mechanical and thermal properties necessary to maintain reliable performance in harsh hydraulic environments. In addition, we are also ready to customize the bushing materials and dimensions according to your special needs. That way, you can be confident that our hydraulic cylinder bushings will provide the optimal performance and durability required for your application.

Advantages Of Tin Bronze Bushings

Tin bronze bushings, like tin bronze with lead content, have several significant advantages in casting processes and hydraulic applications. One is its ability to reduce the crystallization temperature interval of the alloy, which in turn improves the casting performance of the alloy and reduces the wall thickness effect of tin bronze castings. In addition, the addition of lead can also increase the water pressure resistance of castings, thereby making the bushing more resistant to water pressure in harsh operating conditions.

Where Are Hydraulic Bushings Used For ?

Hydraulic bearings play a highly specialized role in maintaining the performance of complex hydraulic systems. They are specifically designed to withstand the loads and forces in various hydraulic applications. Some key components in hydraulic systems that utilize hydraulic bearings include:

Hydraulic Pumps : Hydraulic bearings can be employed in various types of hydraulic pumps to support shafts and other moving components, ensuring the smooth operation of the pump.

Hydraulic Cylinders : Hydraulic cylinders utilize bearings to support the movement of the piston rod within the cylinder, ensuring smooth and stable motion.

Control Arms : In hydraulic control systems, hydraulic bearings can be used to support shafts and control mechanisms, enabling precise and responsive operation.

Hydraulic Cylinder Pins and Bushings : Hydraulic bearings are commonly used in pins and hub connections of hydraulic cylinders to reduce friction and ensure consistent performance.

While the systems that utilize hydraulic bearings are limited, their role is pivotal in various applications. Hydraulic technology has become the cornerstone of many modern industries due to its ability to provide reliable power and control, as well as operate under diverse and challenging conditions. With the assistance of dependable hydraulic bearings, hydraulic systems can maintain optimal performance across a range of operational scenarios.

How To Maintain Your Hydraulic Cylinder Bronze Bushings ?

Heavy equipment such as your excavator represents a significant investment. Ensuring optimal performance and longevity from it is undoubtedly a priority. The key to keeping your excavator in good condition lies in preventive and periodic maintenance, such as regular inspections and maintenance of hydraulic bushings.

Hydraulic system

Assembling two simple parts typically involves three hydraulic cylinders positioned atop them, situated between the main boom, upper boom (rod), and upper boom as well as the bucket (or other additional attachments). To ensure optimal equipment performance, inspect for leaks around or beneath the cylinders.

What to look for when choosing a high-performance hydraulic bushing.

Quality and reliability, acquisition costs, cost savings, equipment size and performance, compatibility, and availability of replacement parts are all crucial factors to consider.

Hydraulic Bronze Bushing For Lift Arms Applications

Bronze bushings are widely used in lift arm applications, especially in mining excavators. They ensure smooth operation, minimize friction, and extend the life of various heavy equipment such as excavators, wheel loaders, hydraulic cylinders, dump trucks, and cranes. These bushings provide crucial support, reduce friction at pivot joints, enable smooth component movement, and enhance excavation efficiency and productivity.

Hydraulic cylinder bushings, including those made of bronze, steel, or plastic, are vital components in hydraulic systems. Bronze bushings stand out due to their self-lubricating properties, which help minimize friction during prolonged compression movements.

When selecting bronze bushings for lift arm applications, factors such as load-bearing capacity, wear resistance, self-lubrication, and maintenance needs must be considered. Bronze bushings are renowned for their durability and cost-effectiveness, especially in challenging environments like mining.

Reliable Hydraulic Bearing Manufacturer

Oiless.co.id is dedicated to serving the hydraulic industry’s needs and has the all necessary equipment and craftspeople to achieve a top-quality product.

Freequently Asked Question

In an extensive global network of service hubs, PrimeServ Omnicare covers maintenance, repair and reconditioning of the many different pieces of equipment that make up your business – in customized contracts that make sense for you.

Excavator bushings find widespread application in components like excavator booms, arms, buckets, as well as in track linkages and idler wheels of heavy equipment. Engineered to endure substantial loads and adverse operational environments, they offer easy replacement when worn or damaged. Maintaining proper lubrication and undertaking regular maintenance routines are crucial for preserving the performance and longevity of excavator bushings, mitigating premature wear and equipment failure.

Oilless bearings serve as pivotal points between the excavator's track chain and its link components. These cylindrical sleeves consist of cast bronze bushings embedded in a solid lubricant, which is pressed into the bores of the link assembly to establish a wear-resistant bearing surface for the rolling of the track chain. The solid lubricant creates a thin film of lubrication between the interacting surfaces, effectively reducing friction, wear, and heat generation. As the self-lubricating material gradually wears, the lubrication layer is consistently replenished, ensuring prolonged, maintenance-free operation.