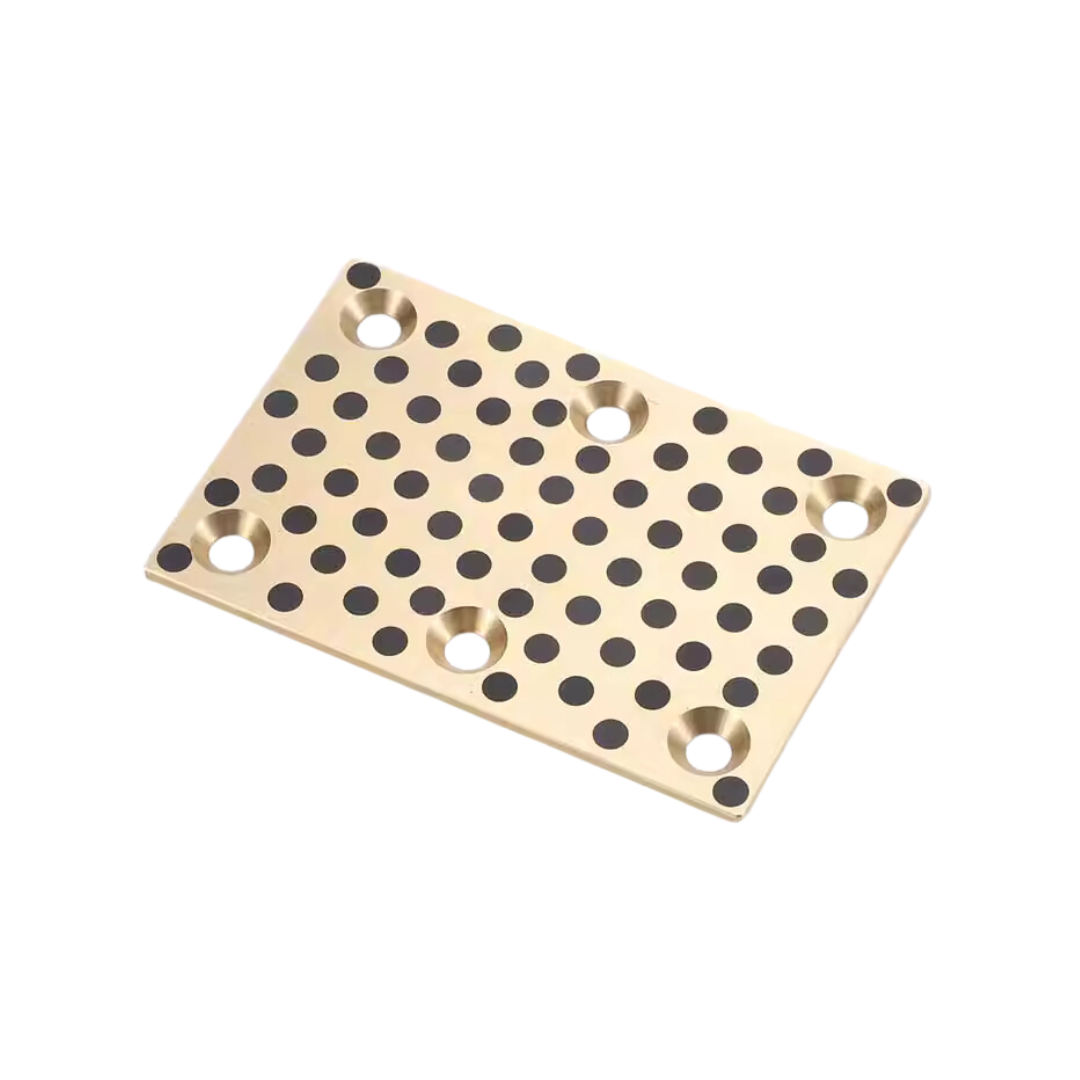

Bronze Wear Plate

Sliding Plate – Graphite Plugged Bronze Wear Plate

The graphite-plugged bronze wear plate combines premium copper alloy with solid lubricant plugs. These bearings are engineered to meet a diverse range of application needs required by modern equipment.

Precise tolerances in site use and strategic plug meshing ensure delivery of optimal lubrication-free performance and service. It utilizes the advantages of copper alloy along with wear-reducing non-metallic materials, making it suitable for a variety of environments including oil-free, high temperature, high load, low speed, dirt, corrosion and radiation resistant conditions.

These slide plates are available in a variety of standard sizes, in both inches and metric units, and can be made to order. Bronze wear plates provide extreme temperature tolerance and high load capabilities, with a choice of journal-style bearings or flat wear plates.

The Application Of Bronze Wear Plate

The bronze wear plate is responsible for most of the load on the metal substrate during the friction process. When friction occurs, the solid lubricant in the hole or slot will transfer or return to the friction surface, forming an even and strong solid transfer layer, which significantly reduces friction wear.

Bronze wear plates are ideal for situations with heavy loads, low speeds, reciprocating or oscillating motion, and other conditions where conventional lubrication is difficult or oil films form. They are also resistant to water, corrosion, as well as acid erosion.

Users generally find that bronze wear plates not only save lubricant and energy, but also have a longer service life than ordinary sliding bearings. They are suitable for a wide range of applications, including metallurgical continuous casting machines, railway supports, rolling equipment, mining machines, ships, gas turbines, and other environments with high temperatures, low-speed heavy loads, intermittent or swinging motion, and other requirements.

Quality Graphite Plugged Bronze Wear Plate Features

Graphite wear plates are most effective in areas requiring constant lubrication, reciprocating motion, or frequent starts and stops, where the formation of an oil film layer is challenging.

The use of bronze wear plates in lubrication-free conditions eliminates the need for additional lubrication equipment. This reduces assembly time and creates a cleaner environment by preventing oil contamination and related issues.

Graphite slide plates demonstrate excellent resistance to wear.

Important Note : If the grinding surface is too rough, optimal wear resistance cannot be guaranteed. Applying grease during initial installation can enhance the performance of slide plates.

Graphite Embedded Bronze Wear Plate To Improve Performance

Graphite wear plates are capable of functioning normally at high temperatures up to 280°C. However, due to their low mechanical strength and weak load-bearing capacity, they are prone to deformation. This drawback can be mitigated by embedding them into metal boreholes, shaping the metal part to serve as a bearing surface, and employing self-lubricating blocks to act as lubricants.

Lubrication mechanism of this kind of self-lubricating bearing

During the sliding friction process between the shaft and the bushing, some molecules of the self-lubricating material are transferred to the surface of the metal shaft to fill in small irregularities and form a relatively stable solid lubricant film. This results in friction between the solid lubricant film and prevents adhesive wear between the shaft and the bushing.

Oil-Free Bronze Wear Plate Manufacture

Oil-free slide plates are available to easily select, configure and order. We offer on-time delivery and competitive prices. This product is made of bronze with graphite, which has a solid lubricating component. This solid lubricated bronze allows use without additional maintenance and lubrication. The wear plate can be drilled from the back and pressed against the sliding surface if necessary, especially if drilling through a solid lubricant depot is necessary.

Bronze Self-Lubricating Wear Strips And Gibs

The wear strips and Bronze Self-lubricating gibs are made of bronze with graphite plugs capable of providing automatic lubrication. This product is suitable for use in a variety of applications up to temperatures of 450°F (232°C). Bronze is a strong material and is resistant to wear, abrasion and deformation under high pressure. The oil-impregnated graphite plug covers approximately 25-30% of the wear surface, forming a self-lubricating graphite layer on the surface. To improve self-lubricating properties, it is recommended to apply a thin layer or light mist of machine oil to new components before use. This will help increase the effectiveness of lubrication. Please note, do not use grease on surfaces that have been impregnated with graphite. This product offers precision machining features on L-Gibs, automatic lubrication, precision ground wear surfaces on wear strips, tight tolerances, consistent quality control and abrasion resistance.