Flanged Bronze Bushing With Oil Groove

Flanged bronze bushings with oil grooves are made from a high quality bronze alloy that has exceptional resistance to wear and corrosion. Manufactured to tight tolerances to ensure optimal fit between the bushing and the shaft or housing.

The flange design of the bushing provides additional stability and support, and helps prevent the bushing from sliding or rotating within the housing.

Oil grooves are strategically placed along the length of the sleeve to provide continuous lubrication of the contact surface between the sleeve and the shaft or housing.

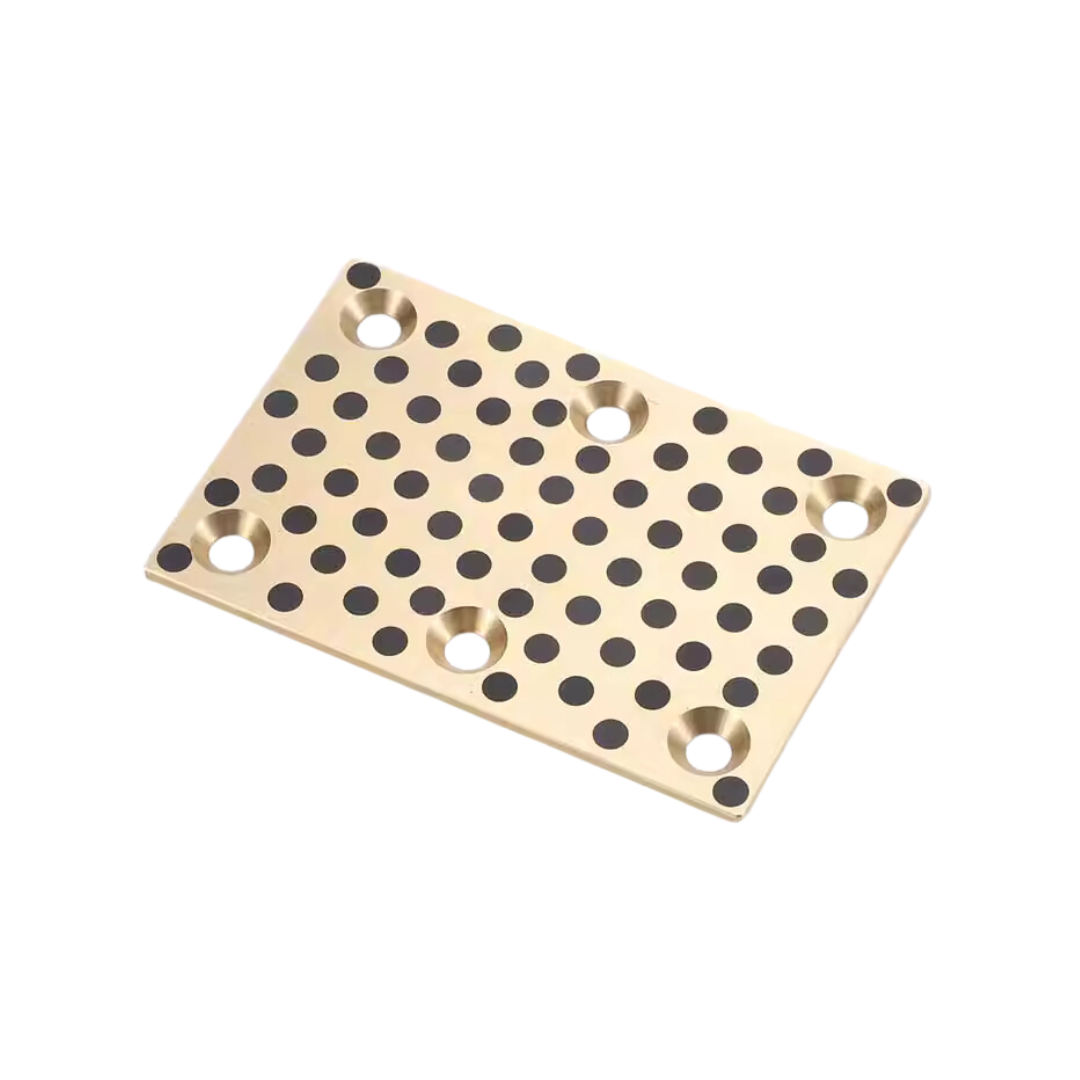

Flanged Sleeve Bearings – Oilless Bushes

Made from cast brass and enriched with self-lubricating graphite, these bearings require no additional lubrication.

They provide a reinforced place for a shaft or other mounting device. In addition, they help reduce the dimensions of the hole or replace worn out original bearings on the wheel.

Their installation can be done by pressing using a vise or hammer. They can also be fastened with adhesive or locking screws.

Flanged sleeve bearings, also known as oilless bushes, are critical components in the machines that power our modern world. Its ability to reduce friction, self-lubricate and contribute to environmental conservation makes it an essential element in various industries.

Costing Save & Maintenance Free Flanged Bronze Bushings

To perform optimally, some bearings often require additional components such as adapter sleeves and bearing holders, which can increase costs and be a hassle to maintain. The emergence of bronze flange bushings has overcome these challenges.

The implementation of flanged bronze bushings that are economical and do not require maintenance is a strategic step for industries that want to increase operational efficiency while reducing costs. The combination of the natural properties of bronze with the flange design makes these bushings a reliable and cost-effective choice for a variety of applications. In the quest for solutions that strike a balance between performance and cost efficiency, flanged bronze bushings are emerging as an important component in the industry.

Crusher Flanged Bronze Bushing Supplier

Flanged bronze bushings, also known as flanged copper bushings or dynamic conical under bushings, are crucial components in crushing equipment, which has a number of aliases such as horizontal bushings or drive shaft bushings.

There are several types of bronze flange bushings in common use, including round flange, method flange, double cut edge flange, single flange, double flange, and copper sleeve with flange, among others. The diameter size used on a crusher is usually determined by the particular model and specifications, which ranges from 0.5 to 3 meters.

Flanged bronze bushings can reduce friction during operation, thereby reducing energy loss and extending equipment service life. This results in reduced maintenance costs and increased efficiency of equipment use. In addition, these bushings also effectively protect the steel parts in contact with them from wear, and are easy to replace when needed.

Loading Grapple Oilless Bearing

Oilless bearings play a critical role in loading grapple applications, especially in environments where traditional lubrication is difficult. The self-lubricating layer made of brass alloy provides stable low-friction performance, even under varying load, speed and temperature conditions.

Brass alloys are chosen for their good mechanical properties and thermal conductivity. When combined with a solid lubricant such as graphite or PTFE, this coating can reduce wear and energy consumption during high-load operations, ensuring durability and reliability during repeated loading and unloading processes.

Under extreme conditions, such as temperature fluctuations and corrosive environments, oilless bearings prevent maintenance problems that may arise from lubricant loss or contamination. They can operate efficiently without conventional lubrication, reducing maintenance costs and downtime.

To select optimal bearings, it is recommended to consult a professional bearing supplier such as Bronzeoilless.com. They can provide expert advice and solutions tailored to specific application requirements, ensuring efficient and reliable grapple operation.

Wholesale Excavators Flanged Bronze Bushing

Excavators and other large machinery and equipment are frequently exposed to harsh environments such as water, gravel, mining sites, and other rugged conditions, placing significant demands on the wear-resistant bushings. These bushings must withstand high-pressure performance requirements, especially in excavator bucket pins and articulation joints.

Utilizing wear-resistant, non-flammable, self-lubricating bucket excavator arm pins, bucket hinge flange bushings, or graphite-plugged flange bronze bushings can significantly enhance the lifespan of excavators and other equipment. This, in turn, improves equipment utilization rates, reduces maintenance and repair costs, and enhances overall operational efficiency.

Flange Bushings by Size

- Standard bronze flanged bushing

- Flange bushings for large crushers and excavators

- Customized flanged bronze bushings to the size you need