Bronze Thrust Washer

Bronze thrust bushings are critical components used in a variety of industrial applications, especially in situations where bearings must endure high axial loads at low speeds. These washers are designed to prevent movement along the shaft axis, acting as a resistance that keeps components in position while reducing friction.

How does a Bronze Thrust Washer Work ?

Bronze thrust washers work by separating two rotating parts and providing a low-friction surface that allows them to move smoothly. The washer is placed between two rotating parts and helps transfer the load from one part to the other. The bronze material used in thrust washers provides excellent wear resistance and durability, making it an ideal material for use in high load applications.

We have developed bronze thrust washers for use in applications with high loads and low speeds, made from high-strength rotating cast bronze using specially designed graphite plugs as lubricants.

Our range of bronze thrust washers is available in various metric and imperial sizes. Our in-house machining services can produce non-standard sizes to meet specific customer needs.

To select the right size of bronze thrust washer for a particular application, the following steps can be taken:

- Measure the dimensions of the shaft and housing.

- Consider the operational load applied.

- Consult with us to select the appropriate size of thrust washer based on the specific application requirements.

Self-Lubricated Bearing Thrust Washer Technology

Bronze Thrust Bearing Material : You can also use a self-lubricating bronze component configurator. The selection of thrust washer materials is determined by the application. Material selection is determined by several factors such as speed, load, and temperature. Thrust washers can be made of plastic, brass, bronze, stainless steel, graphite, or various other materials. Whatever your application, OILESS technicians will help you determine the most cost-effective material and production process to meet your needs and those of your customers. Contact OILESS today so we can solve your customer’s problems. Our portfolio offers maintenance-free oil-free bronze bushings for high loads and long life according to customer drawings and common standards (VDI/BAK, NAAMS).

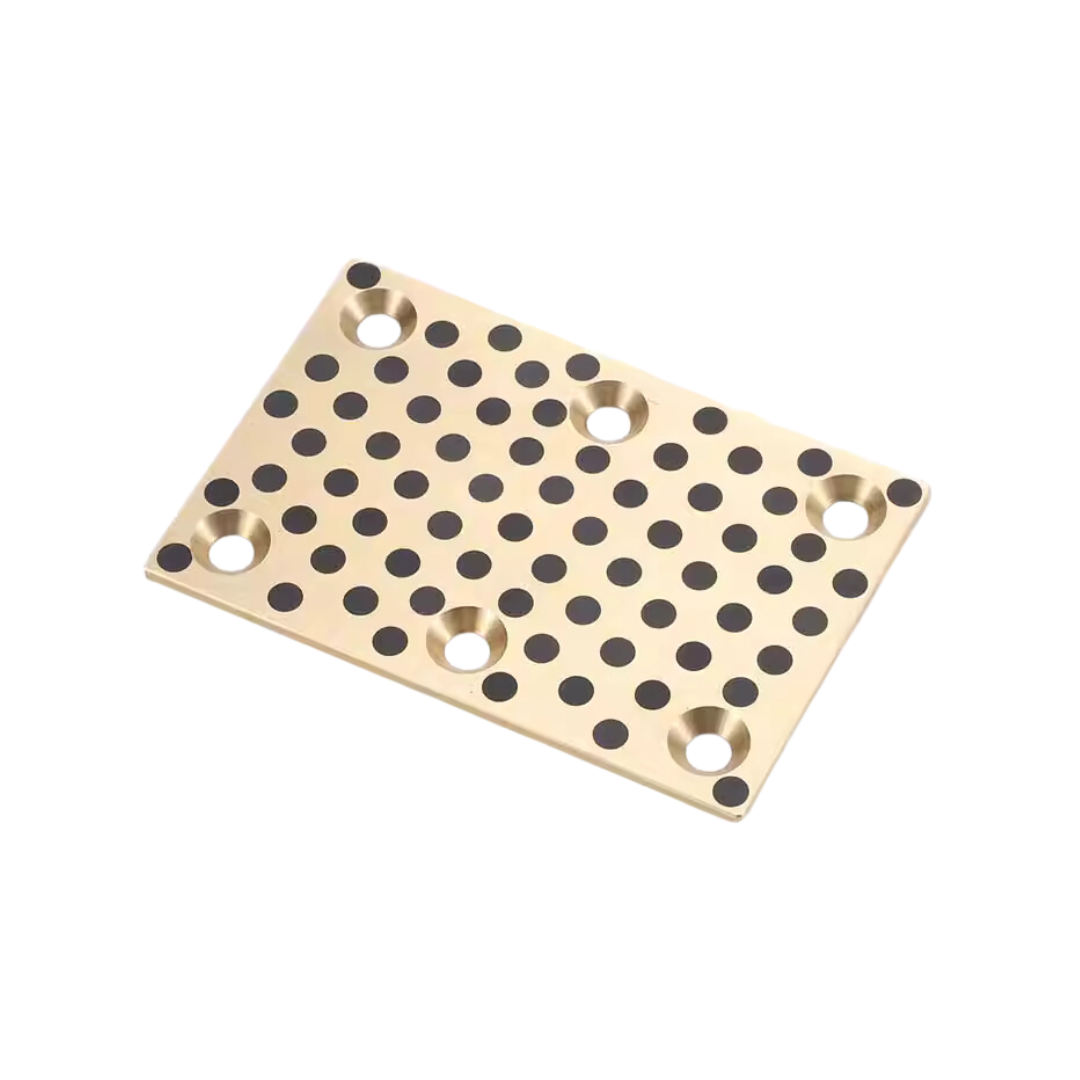

Clutch Hub Thrust Washer Bearing

Bronze Thrust Washers Used in Vehicles : Bearings play a crucial role in vehicle performance. In terms of reliability, once damaged, it will affect vehicle handling. In terms of safety, the installation position of some bearings is crucial, such as wheel hub bearings which support the weight of the entire vehicle. Any error in installation will affect the safety of the entire vehicle. In terms of comfort, bearings not only have a direct impact on the smooth operation of the vehicle, but poor-quality bearings are also prone to producing louder noise. Although thrust washers are small components, they are closely related to the overall reliability, safety, and comfort of the vehicle.

What Is A Bronze Thrust Washer ?

Bronze Thrust Washer bearings are flat bearings typically inserted between rotating and stationary components, serving to keep the rotating components in place by providing something to rub against if they start moving sideways. OILESS bronze thrust washer suppliers are made from self-lubricating materials that support dry and maintenance-free operations for various applications and axial load requirements. All our materials undergo rigorous testing by our professionals to ensure long service life and high wear resistance.

Where Are Bronze Thrust Washers Used?

They are utilized in applications with high levels of wear such as axle assemblies, motors, transmissions, pumps, power take-offs, and winches. Nearly all applications requiring wear-resistant surfaces.

Precision-designed thrust washer bearings are employed in high-wear applications such as transmissions, power take-offs, pumps, axle assemblies, motors, and winches. The thrust washer kit includes thrust washers of various thicknesses for proper installation during component assembly. Standard thrust washers are manufactured for products like automotive engines.

Turbocharger Washer Thrust Bearing

Turbochargers are vital products in energy savings that can improve engine performance, reduce fuel consumption and reduce pollution. Thrust bearings are key components to ensure smooth operation and overall device longevity. These bearings must not only have optimal physical and mechanical properties, but must also offer superior friction and wear characteristics.

Factors to consider when selecting Bronze Thrust Washer

- Load Capacity

- Speed Capability

- Temperature Range

- Environment and Application & Cost

The Advantage Of Oilless Thrust Washer

Thrust washer bearings can operate in situations where roller bearings are impractical, inconvenient, or offer no advantages, such as very high operating speeds, particularly significant shocks and vibrations, limited radial space dimensions, or the need for splitting and mounting, as well as working in water or corrosive media.

- Excellent fatigue strength

- Reduced friction and excellent wear resistance

- Good corrosion resistance

- Good friction compatibility

- Excellent embedding

- Higher load-carrying capacity

- Good thermal conductivity, manufacturability, and economy

How To Choose Bronze Thrust Washer Bearing Material

Bronze Thrust washers can be found in nearly every piece of equipment, machinery, transportation device, electric tool, and recreational device that involves moving parts, shafts, bolts, pins, bearings, and rotating components. In its simplest form, a thrust washer is a flat bearing that has long been used in washing machines to transmit and resolve axial forces in rotational mechanisms to keep components aligned along the shaft. Thrust washers are an economical alternative to roller thrust bearings whenever moderate force speeds are involved.

When selecting bronze thrust washer materials, the following aspects should be considered: types of loads, load sizes, journal speeds, operating temperatures, corrosive conditions, oil supply methods, appropriate thrust plate hardness, contamination conditions, economic performance, etc.

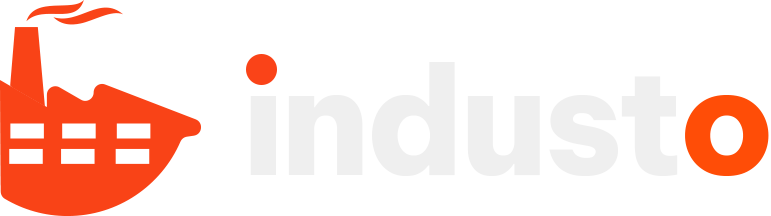

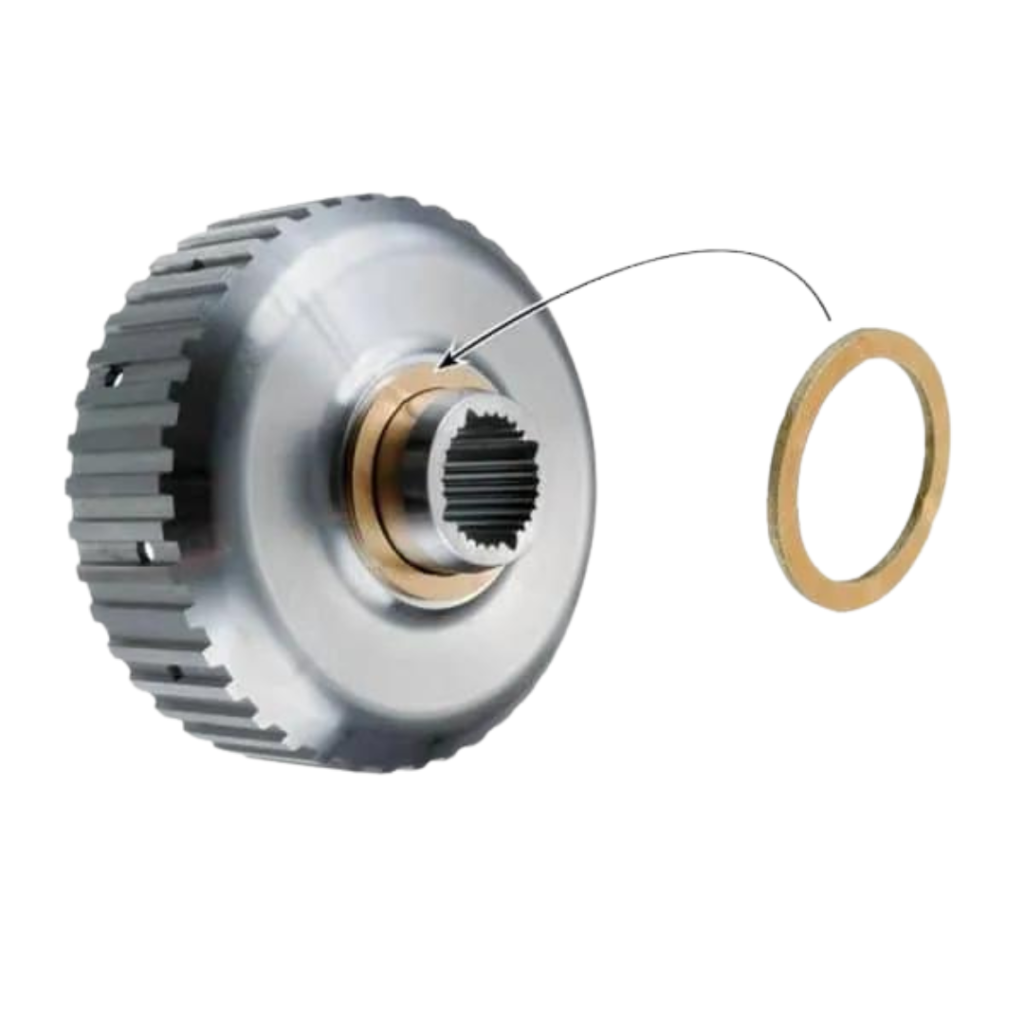

Bronze Graphite Thrust Washers

The Graphite Bronze Thrust Washer is a high-performance solution for applications demanding durability, low friction, and excellent load-bearing characteristics. It is designed to thrive in conditions where traditional lubrication is difficult or impossible. Here’s a brief overview:

The Graphite Bronze Thrust Washer is a type of thrust washer made from bronze alloy and impregnated with graphite plug. Bronze provides strength, wear resistance, and excellent heat dissipation, making it suitable for high-speed applications. Graphite, on the other hand, offers self-lubricating properties.

This combination of materials results in a thrust washer capable of handling high load capacity and speed without requiring routine maintenance or additional lubrication. The automatic lubrication feature of graphite makes this thrust washer ideal for applications in hard-to-reach areas or environments where routine maintenance would be difficult or disruptive.

Common applications for Graphite Bronze Thrust Washers include heavy machinery, automotive components, and various industrial equipment. Its durability and low-maintenance characteristics make it a popular choice in demanding environments.

At Oiless.co.id, we offer a range of Graphite Bronze Thrust Washers in various sizes and specifications to meet your unique application needs. If you’re looking for a reliable and high-performance solution, our Graphite Bronze Thrust Washers may be the right choice.