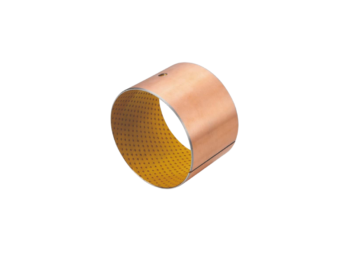

Solid lubricating bearings play an important role in maintaining operating stability when exposed to heavy loads. Its lubrication mechanism, along with unique material properties, enable it to meet these challenges well.

Bearings use a solid lubricant that forms a lubricating layer on their surface. This coating effectively reduces direct contact between the bearing surface and opposing parts, avoiding excessive wear due to heavy loads. The shear strength of solid lubricants is low, which means that during movement, the friction between metals is converted into friction between solid lubricants. This reduces the coefficient of friction and wasted energy.

Solid lubricants are generally resistant to high temperatures and pressures, as well as wear. This ensures the stability of the lubricant film even under conditions of heavy loads and high temperatures. Special materials and designs can also increase the bearing’s ability to withstand loads.

During use, the lubricant layer can adjust and repair automatically. When the bearing receives heavy loads, the lubricant layer will thicken to provide better lubrication. The particles in the lubricant also fill micro-cracks in the surface, maintaining the smoothness and integrity of the bearing.

With its lubrication mechanism and material characteristics, solid lubricant bearings maintain operating stability under heavy loads, extend bearing life, and improve equipment reliability and efficiency.