24/7 ONLINE SUPPORT

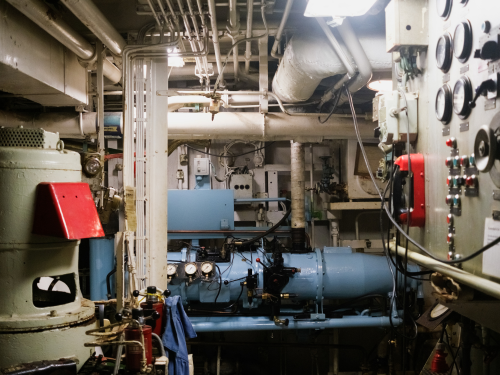

Marine Machinery

Smoother, Safer – Oiless Marine Bearing

By maximizing all that a marine vessel has to offer, it is important to invest in solutions that make the vessel more stable and balanced. Minimizing rollovers can not only make a major contribution to the safety of passengers and crew, but also improve fuel economy and overall vessel performance.

Your Best Marine Bearing Supplier – Safety And Reliability

Marine bearings play an important role in connecting the main engine with the propeller, transmit power from the main engine to the propeller in the ship’s power system, and are a key component of the entire ship’s power unit. Ensuring the safe, efficient and smooth operation of marine bearings is an important factor for normal ship navigation.

We combine technical expertise in Marine bearings, proven design and precision manufacturing with a deep understanding of shipboard challenges. The result is a system analysis based on vessels and marine bearings that is optimized according to your vessel’s specific requirements.

We are steadfast in our belief in providing the highest quality marine bearings.

Marine Machinery Bearing – Heavy Equipment Parts

Marine bearings are a crucial component of ship engines and marine diesel engines used on ships, and this rule is no exception. Bearings play a role in reducing friction, specifically by converting sliding friction into rolling friction.

To maintain quality control, the manufacturing process is carried out internally. The tin base material is applied centrifugally to the journal bearings and cast statically for the thrust bearings. They are metallurgically bonded to the bearings to achieve maximum operational efficiency, and all materials meet or even exceed the specifications and standards required for use on ships.

Oiless Bearings performs a variety of non-destructive testing, including ultrasonic, liquid penetration and visual inspection, to ensure product integrity. Additionally, solutions can also be designed to withstand shock loads.

Marine Bronze Bushing – Self Lubrcating

Self-lubricating Marine Bearings are a commonly used component in ship equipment. As in land machines and equipment, almost all types of machine and equipment bearings use bronze bushings, and copper bushes are often used as self-lubricating bearings. Its application to ship equipment is very broad because ships generally operate in oceans, lakes and rivers which often come into contact with fresh water and salt water. Due to frequent contact with water, especially sea water containing corrosive substances and high water pressure, marine bearings must have pressure and corrosion resistance. Therefore, the selection of materials for making marine bearings must comply with the provisions for selecting materials that suit your needs.

Marine Bearings – Bearing Manufacturers

Marine Bearings ensure exceptional service life with virtually no swelling in seawater and a very low coefficient of thermal expansion, providing dimensional stability in Arctic and tropical seas. In addition, this material does not cause corrosion of the housing and shaft and is resistant to edge loading and misalignment. Marine bearing materials can be used together with water and grease lubrication, and in a dry state for a limited period of time. Oiless.co.id uses special bearing surfaces to expand its dry operating capabilities, reduce friction and wear rates, and can be used with oil and water lubrication.

Critical Parts Of Steam Turbines – Bearing Bronze With Graphite Insert

Some common steam turbine failures can result in long downtime and high costs. Choosing to repair rather than replace a steam turbine is often the most cost-effective and quickest solution.

We offer inspection, basic repair and advanced repair services for all types of steam turbines, whether used in the marine, power or other industries. After carrying out a detailed inspection, condition assessment, and compiling a report, Oiless.co.id proceeded with repairs, which included manufacturing or reconditioning important components such as journal bearings, thrust bearings, and bronze bearings with graphite inserted reduction gearboxes, among others.

In addition to our expertise and proven track record, we also offer fast response times and short lead times to minimize downtime for our customers. Don’t hesitate to contact us for any needs you may have.

Oiless Response To Demand For Highly Reliable Turbocharger Bearings In The Marine Industry

Optimize your ship’s operation with condition-based maintenance