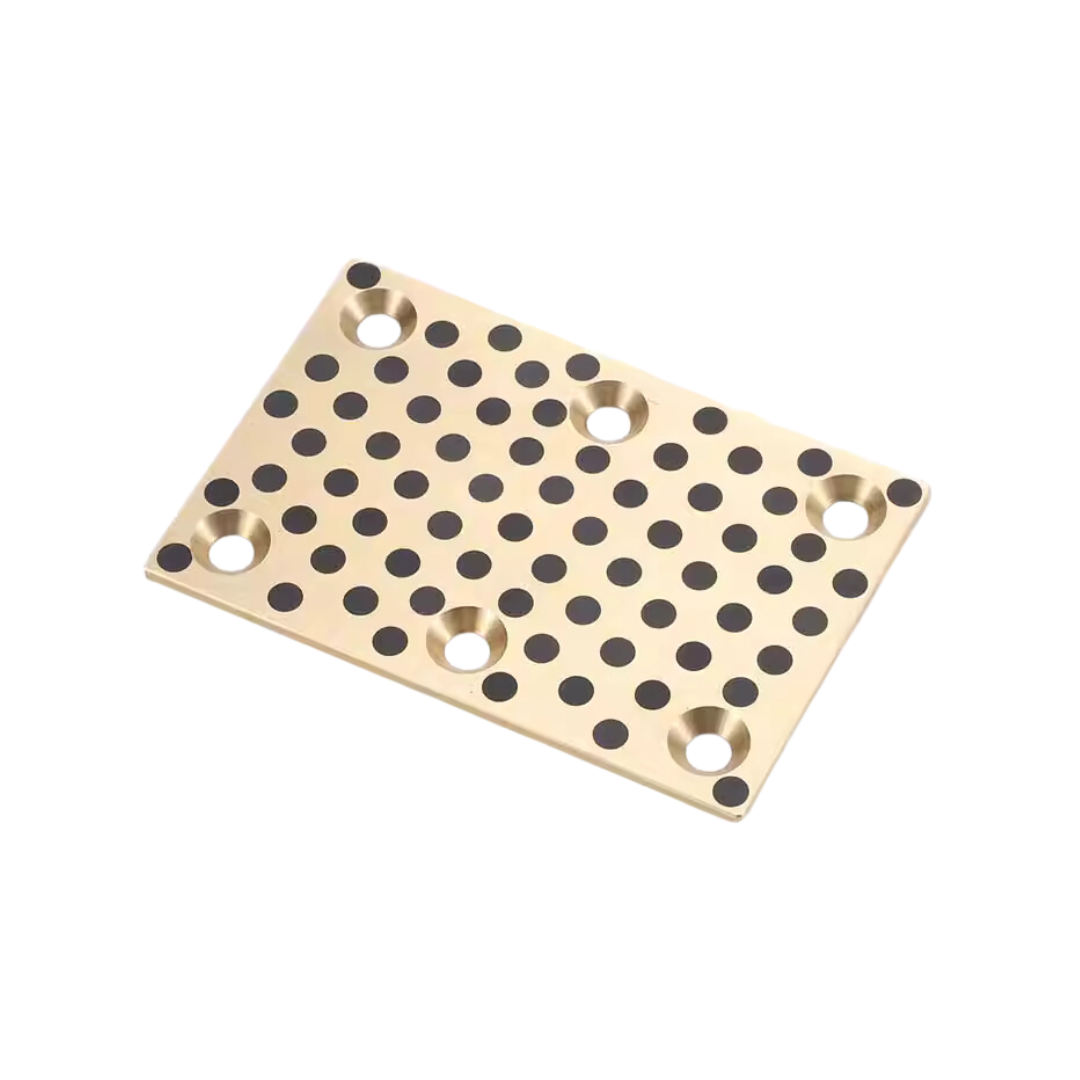

Oiless Bushing

Oil-free bushings, also known as plain bearings, are friction-reducing products designed to operate without the need for oil and resist wear. Combining graphite with bronze, these bushings feature a remarkably low coefficient of friction, thus minimizing wear on both the shaft and the bushing body.

Specifically engineered for high-load, low-speed applications, these bushings are made from high-strength centrifugally cast bronze infused with specially molded graphite plugs to serve as lubricants.

Oilless Bronze Bushing Widely Used In :

Automobiles / motorbikes / machine tools / molds / textiles / printing tobacco/pharmaceutical/food machinery/instruments/oil pumps/cylinders / hydraulic parts/valves / pneumatic components/engines / internal combustion engine spindle and connecting rod bearings / micro motors/power tools/lifts/cranes/construction/metallurgy/mining/engineering machinery / lifting equipment / forging machine tools/marine/petroleum/shipbuilding industry machinery / Bridge engineering/water conservancy/hydropower/steel industry, etc.

How Does Oilless Bushing Work ?

Oilless bushings are a type of specially designed bronze sliding bearing, using maintenance-free solid lubricants such as graphite and polytetrafluoroethylene (PTFE). This integration significantly improves its performance and durability in dry and high-temperature environments. These bushings excel in extreme working conditions, including oil-free, high-temperature, high-load, low-speed, contamination-resistant, corrosion-resistant and radiation-resistant environments, and can operate stably underwater and in vacuum conditions.

Crafted from a high-strength copper alloy, these oilless bushings provide excellent self-lubricating performance by combining graphite and PTFE into the bronze material. This combination not only reduces the coefficient of friction but also significantly reduces wear between the shaft and body. The oilless bushing design ensures consistent performance over different temperatures, loads, movements and environmental conditions, making it well suited for high load and low speed applications.

Compared to traditional lubrication methods, oilless bushings offer significant advantages in overcoming friction interfaces. On traditional unlubricated contact surfaces, friction and wear are usually caused by phenomena such as sliding, stick-slip, and plastic deformation. Although traditional lubricants can reduce this problem to a certain extent, they may be trapped under conditions of high contact area, thereby causing phenomena such as dry friction or boundary lubrication. Oilless bushings effectively avoid these problems through the continuous lubricating action of their own lubricating material, thereby ensuring equipment reliability and stability under a wide range of working conditions.

Types Of Oilless Bushing

Self-lubricating bushings, also known as oilless or dry bearings, find applications across various industries where conventional lubrication methods are impractical or undesired. These bushings offer exceptional wear resistance and low friction levels without the need for additional lubrication. The market provides several options of oilless bushings, each tailored to specific applications:

Graphite Bronze Bushings: Comprising a bronze alloy mixed with graphite, these bushings possess self-lubricating properties and enhanced wear resistance, making them ideal for high-load, low-speed applications in industries such as automotive and construction.

Cast Bronze Bushings: Manufactured from a bronze alloy with a porous structure serving as a lubricant reservoir, these bushings require no additional lubrication and are suitable for heavy-duty equipment such as construction and mining machinery.

Sintered Bronze Bushings: Produced by compressing bronze powder and impregnating the pores with solid lubricants like graphite or PTFE, these bushings offer excellent wear resistance, heat dissipation, and load-bearing capacity.

Bimetal Bushings: Consisting of two layers of different metals, typically an inner layer with low friction and wear resistance and an outer layer providing durability, these bushings combine low friction, wear resistance, and high load-bearing capacity.

Loading Grapple Oilless Bearing

Oilless bearings play a critical role in loading grapple applications, especially in environments where traditional lubrication is difficult. The self-lubricating layer made of brass alloy provides stable low-friction performance, even under varying load, speed and temperature conditions.

Brass alloys are chosen for their good mechanical properties and thermal conductivity. When combined with a solid lubricant such as graphite or PTFE, this coating can reduce wear and energy consumption during high-load operations, ensuring durability and reliability during repeated loading and unloading processes.

Under extreme conditions, such as temperature fluctuations and corrosive environments, oilless bearings prevent maintenance problems that may arise from lubricant loss or contamination. They can operate efficiently without conventional lubrication, reducing maintenance costs and downtime.

To select optimal bearings, it is recommended to consult a professional bearing supplier such as Bronzeoilless.com. They can provide expert advice and solutions tailored to specific application requirements, ensuring efficient and reliable grapple operation.

Application Of Oilless Bushing

Oilless bushings, known for their self-lubricating capabilities and durability, are becoming popular in various industrial sectors. It is usually made of bronze and contains solid graphite lubricant inside, ensuring optimal lubrication performance in a variety of work situations. These bushings can handle high PV values and adapt to different loads, speeds and temperatures, maintaining equipment stability and reliability over time.

In continuous casting and rolling mills, oilless bushings reduce wear due to high temperatures and heavy loads, improving production efficiency and product quality. On mining equipment, they maintain consistent performance in harsh environments, reducing maintenance costs. In addition, ship engines and turbines also benefit from their resistance to corrosion and wear, extending equipment life.

Oilless bushings also play a crucial role in the injection molding and automotive molding industries, keeping the coefficient of friction low under high loads and speeds, which in turn increases energy efficiency and production yield. Its stable physical properties ensure consistent dimensions under various conditions, reducing deformation and maintaining mold accuracy and product consistency.