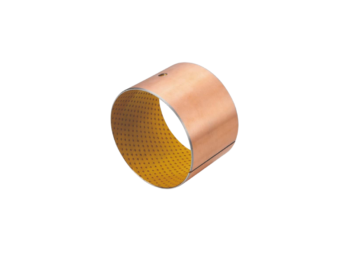

Performance in High-Temperature Environments:

- High-Temperature Resistance: Solid lubricated bearings utilize specialized materials resistant to high temperatures, such as graphite copper alloys, to maintain stable performance even under high-temperature conditions.

- Self-Lubricating Capability: In high-temperature environments, solid lubricated bearings rely on self-lubrication to sustain operation without dependence on external lubricants.

- Creep and Oxidation Resistance: Bearing materials must exhibit good resistance to creep and oxidation to prevent performance degradation and structural damage at high temperatures.

Performance in Low-Temperature Environments:

- Ultra-Low Temperature Bearings: Some bearings are specifically designed to operate in extremely low temperatures, such as in liquid nitrogen or cryogenic gas pumps.

- Consistent Lubrication Performance: Despite low temperatures, solid lubricated bearings maintain effective lubrication due to the use of solid lubricant materials like PTFE or graphite.

- Anti-Brittleness: Bearing materials must remain tough and resistant to impact at low temperatures to prevent brittleness.

Performance in High-Humidity Environments:

- Corrosion Resistance: Bearing materials must withstand corrosion in humid environments to prevent degradation.

- Waterproof Performance: Bearing designs must optimize waterproofing to prevent the ingress of water and moisture that could affect lubrication.

- Anti-Adhesion: Bearing lubricant materials must possess anti-adhesive properties to reduce friction and wear in high-humidity environments.

Overall, the performance of solid lubricated bearings in extreme environments depends on their design, materials, and manufacturing processes. With the proper approach to material selection and design, bearings can deliver reliable performance in extreme conditions such as high temperatures, low temperatures, and high humidity.