Wind Energy

The Use Of Bearings In The Wind Energy

The wind power generation industry is facing enormous pressure to reduce costs per MWh by making turbine design improvements, improving performance, and increasing reliability, while also reducing maintenance costs.

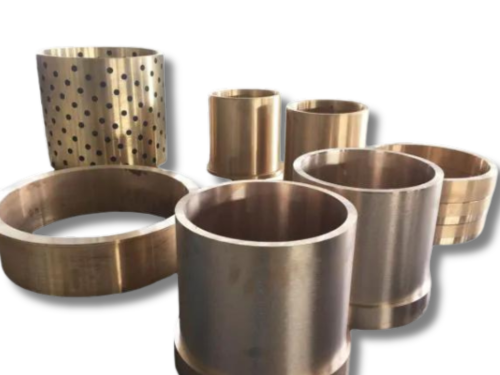

The unique characteristics of oilless bushing bearings make them especially suitable for the harsh conditions in wind turbines. These conditions include extreme temperatures, high loads, and constant exposure to the elements.

Wind Energy – Reduce The Levelized Cost Of Energy

In the realm of renewable energy, wind power is a very powerful force. To utilize this energy efficiently, the engines that drive wind turbines must be powerful and reliable. One important component that contributes to the success of a wind energy system is the oil-free bushing bearing.

Oilless bushing bearings from Oiless.co.id have been optimized to improve turbine performance, reliability and energy output. We design and develop bearings, seals, condition monitoring systems and lubrication systems that enable more cost-effective wind energy generation and use lower consumption lubricants.

Applications In Wind Turbines

The main rotor shaft often uses oilless bushing bearings to ensure smooth rotation and minimize wear even when subjected to heavy loads and dynamic forces.

In pitch control systems, precise and reliable movement is critical to optimizing energy production. The use of oil-free bushing bearings guarantees the flexibility and durability required in this system.

In wind turbine generator assemblies, the use of oilless bushing bearings contributes to the long life and efficiency of rotating components.

Demanding Loads And Harsh Operations

The main shaft arrangement in a wind turbine can be a geared, hybrid, or direct drive design. However, in all such settings, the shaft must be able to withstand axial and radial loads and operate in harsh and changing conditions.

Wind turbine main shaft bearings rotate at relatively low speeds, about 10 rpm, and they are constantly subjected to variable loads. In offshore applications, turbine bearings may be exposed to corrosive seawater. The bearings on the largest turbines have internal bores of more than 2 meters. Due to the high costs and technical difficulties of replacing turbines, operators want them to last for a 25-year operational life.

Operation and Maintenance

If you’re facing a difficult design challenge, need to simplify your maintenance and lubrication routine, perform a short-term repair, or a long-term upgrade, Oiless comprehensive portfolio can help. Our wind energy solutions include a range of advanced design, maintenance, repair and refurbishment services that support wind turbine manufacturers and operators.

Stay Competitive And Solve Your Technical Challenges

Oiless.co.id can help you to take full advantage of the available wind and optimize your energy output while reducing your operating costs.